The most basic test apparatus to determine the corrosion resistance of the metal and their finishings. Applicable to ISO 09227 and others, SUGA pursues for uniformity in results and reproducibility.

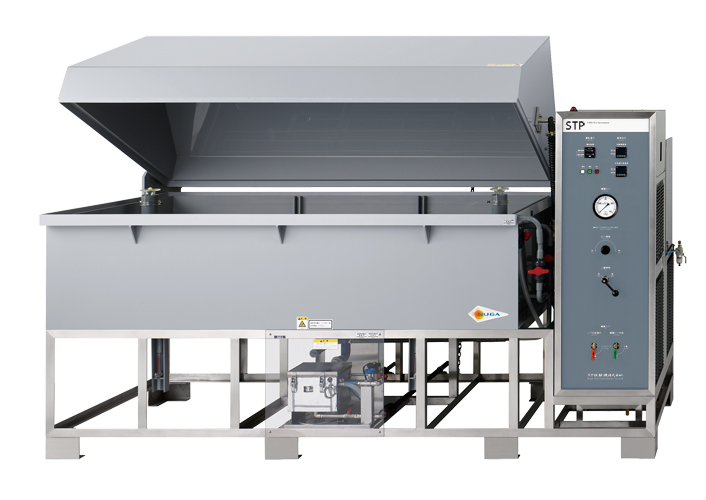

Table-top type with compact design.

STP-30 is not only able to be installed in a small space such as a table but also can perform on ISO 9227:2017 which is the most basic salt spray test method among corrosion acceleration tests to evaluate the corrosion resistance of metallic materials. It is widely used for quality control and acceptance inspection.

Conforms to the latest version of ISO 9227:2022

The TM Mist Saving Dispersion Tower sprays a salt solution uniformly / CASS liquid into the test chamber to test the corrosion resistance of metal materials and surface treatments.

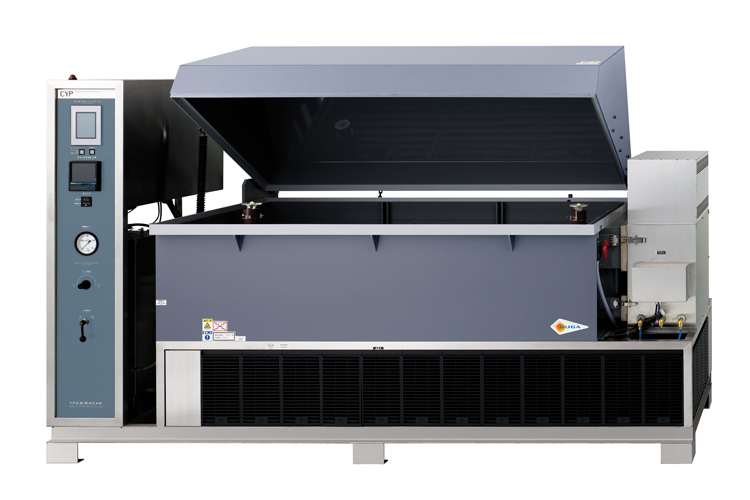

Tests multiple / large-sized specimens at once

These instruments are capable of testing large number of specimens with its large-sized test chamber. The increased floor load resistance option allows the instrument to test large-sized specimens and full-scale and products.

STP-90VR is capable of even distribution of salt spray test solution onto the specimen at a precision much greater than before.

Our standard model acknowledged as the leader in humidity testing

This is a test instrument for evaluating the humidity resistance of paint (ISO 6270), rust preventive oil (JIS K 2246), and metal surface treatments such as coating and colorants. Its chamber lid designed so that water particles adhered on the ceiling will not fall onto the specimens, giving it outstanding test reproducibility.

To reproduce the various environment products and materials face in real life, SUGA offers excellent correlation with outdoor exposure results, and acceleration.

SUGA will correspond to various needs such as standard based specification and/or special specification.

User-friendly design

CCT-1LM is easy to put in and take out large sample by slide door. By new designed mist dispersion tower, it is possible to uniformly spray salt solution and secure a wide space. It does not prevent a flow (movement) line regardless of large slide door that improves workability. The floor is not soiled by water drops sticking to inside the door.

Conforms to JASO M 609:2024

This is a combined cyclic corrosion test instrument capable of performing salt spray, dry, humidity, and outside air intake tests either independently or in combination.

World standard model for cyclic tests

This is a compact combined cyclic test instrument capable of either single or combination of salt spray, dry, humidity, and open air tests. It is widely used both in Japan and in overseas as a standard combined cyclic test instrument capable of performing JIS, JASO, and ISO cyclic tests.

Tests multiple / large-sized specimens at once

This is a large-sized combined cyclic test instrument capable of either single or combination of salt spray, dry, humidity, and open air tests. It is capable of testing large number of specimens at once. With the increased floor load capacity option, large-sized specimens and full-scale models and products can also be tested.

Determines the outdoor durability of numerous materials and products

This is a compact combined cyclic weather meter capable of simulating various harsh outdoor conditions via combination of light, salt spray, dry, humidity, salt immersion, low temperature, and water washing tests.

Determines the outdoor durability of photovoltaic modules

This model performs accelerated weathering tests on photovoltaic modules, simulating various harsh outdoor conditions. Up to two full-scale photovoltaic modules can be tested.

Determines the outdoor resistance of large full-scale products

This combined cyclic test chamber simulates various harsh outdoor conditions (light, acid rain spray, dry, humidity, dew and low temperature) in combination of the user's choice. It is capable of testing large-sized materials and full- scale products sush as automobiles and motorcycles.

SUGA also offers Exaust Air Treatment Unit for Corrosion test instrument and Automatic solution supply unit.

No more worries about damage

Made of highly durable resin material, significantly reducing the risk of damage during handling.

If there is any abnormality in the spray, it can be disassembled and cleaned with running water.

Contributes to reducing energy consumption in the solution supplying process

This unit automatically detects the water level in the corrosion test instrument's solution tank, and supplies water when necessary. This is best suited for tests that take long period of time. It includes an air barrier board, which prevents the pH level of the solution from changing. SS-2's water tank can hold up to 100 liters. Models with more solution capacity and capability of generating solutions are also available.

Any products and materials around us are exposed to Ozone and corrosive gases. The reliability of the test results depend on the accurate control of the gas concentration, temperature, and humidity. SUGA assures the reliable test results.

Instrument capable of accommodating tests with and without Cl2

GT-100 is used to evaluate the corrosion resistance of electronic components and plated products against pure or mixed gases of SO2, H2S, NO2 and Cl2. Exchangeable test Chamber for both conducting test using chlorine as well as tests not using chlorine. More stable control of the gas density, temperature, and humidity by preventing condensation system.

Heat aging test complying with ISO 188

TG100 is a heat aging test instrument that conforms to the new ISO 188-2007, an important standard for determining the lifespan of rubber and plastic materials. The air replacement rate is set by the easy-to-operate flow rate meter as recommended by ISO. Accurate testing can be performed with minimal limitations on installation location.

True ozone control made possible with pursuit of accuracy

This instrument performs accelerated ozone degradation testing for organic materials (such as rubber) used in automobiles and electronic materials. Its fully closed system allows for true ozone concentration tests. Applicable to ISO 1431-1 standard.